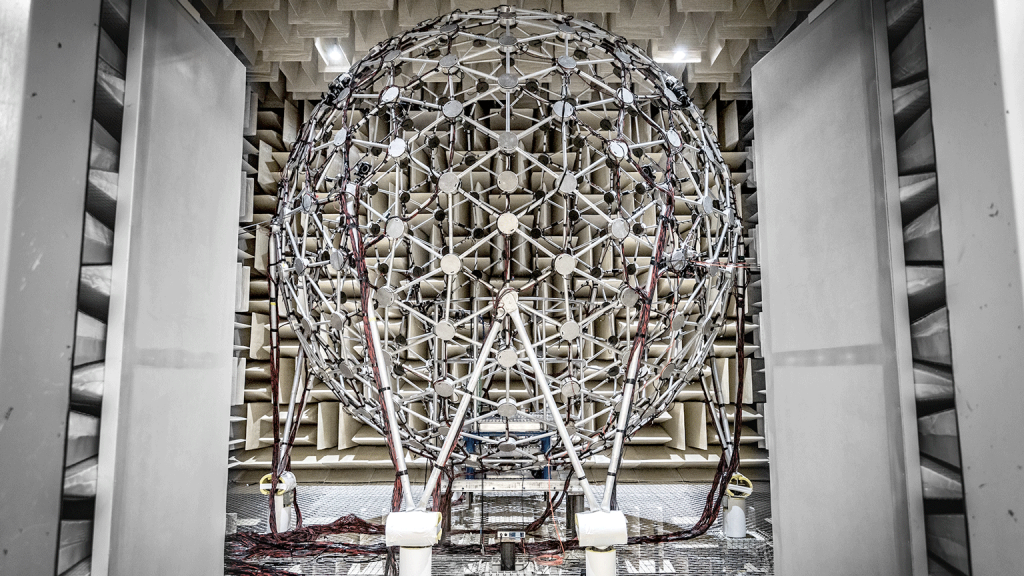

Anechoic Chambers

Full and Hemi-Anechoic Chambers

Eckel’s Full and Hemi-Anechoic Chambers are custom-engineered structures designed to create the ideal acoustic environment in which to conduct testing and research within an array of industries and disciplines. These state-of-the-art echo-free enclosures have a sound energy absorption level of 99+% and are precision-designed and custom-fabricated to the meet the frequency specifications required to achieve exacting scientific and product testing goals.

Full Anechoic Chambers

Acoustic treatment on the walls, ceilings and floors Designed for:

- Loudspeakers, microphones, electrical components

- Telecommunications and computer equipment

- Clinical audiology research

Full anechoic chambers feature a working floor that allows wedges to be installed on all surfaces of the chamber

Hemi-Anechoic Chambers

Acoustic treatment on the walls and ceilings only Designed for:

- Automobiles and ATVs

- Construction equipment

- Major appliances such as washers, dryers, refrigerators

Hemi-anechoic chambers feature a solid floor to accommodate vehicles and heavy equipment

Chamber Construction

The type of product being analyzed and the nature of the data to be collected determines chamber size, outer structure, and most importantly the geometry and design of the proprietary acoustic treatment used to achieve the set performance goals. Using that information, each chamber is precision-engineered and custom-fabricated to the meet the frequency specifications required to achieve the testing criteria set forth by the customer.

Attenuating Structures

In order to obtain a suitable acoustic environment, the anechoic wedges should be installed in a proper noise and vibration isolating structure. This enclosure may be one of several types of construction built on an isolated floor, or floated on springs or other vibration isolation material.

Wedge Technology

The key performance element of Eckel’s Anechoic Chambers is their patented sound-absorbing wedges. Eckel Wedges and sound absorbing elements have a low frequency cut-off Hertz. Above this frequency, they have a 0.99 coefficient of absorption, or a ratio of reflected sound pressure to incident sound pressure of 10% or less.

Eckel anechoic chamber linings represent the most advanced thinking in sound absorbing wedge design. The type of product being tested in the chamber will determine the cut-off frequency of the chamber wedges. Eckel wedges are available in a range of cut-off frequencies from 60 Hz to 250 Hz or higher.

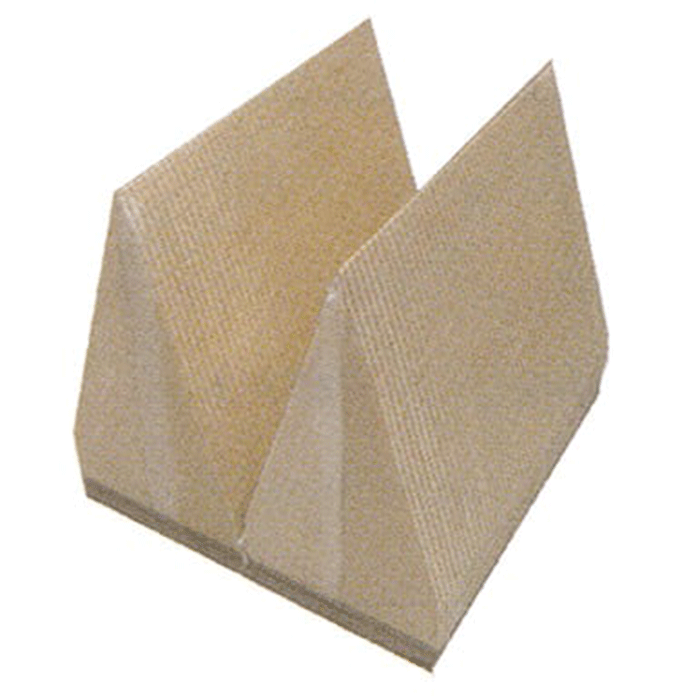

Standard Wedge

Eckel’s classic wedge design offers maximum broadband performance. These cloth-covered, fiberglass wedges are commonly used for testing speakers, microphones and handheld devices.

Perforated Metallic

This wedge design represents the execution of the classic design with a perforated metal cover replacing the original cloth covering. These cleanable and highly durable wedges are typically installed in chambers for testing automotive products and major appliances.

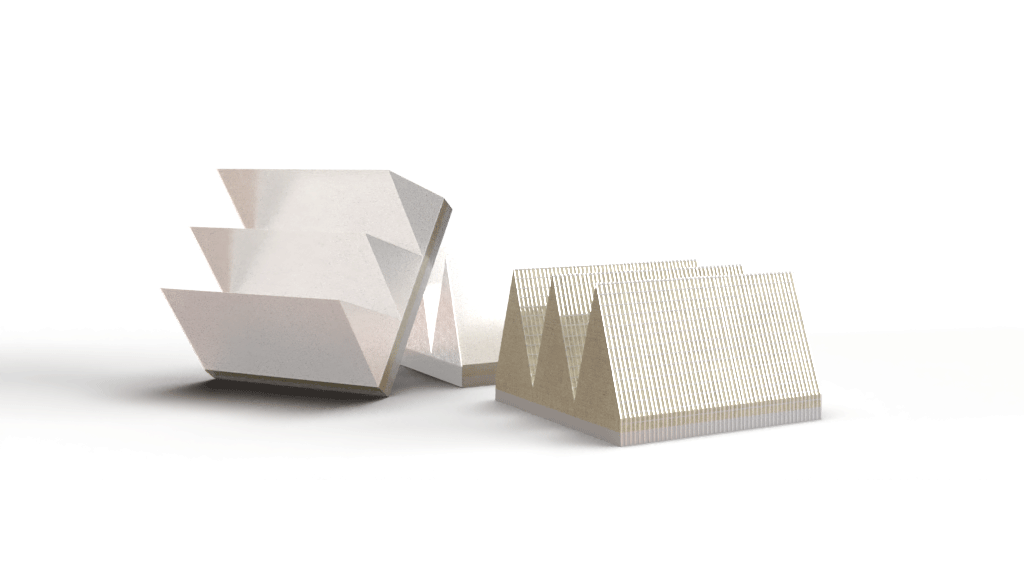

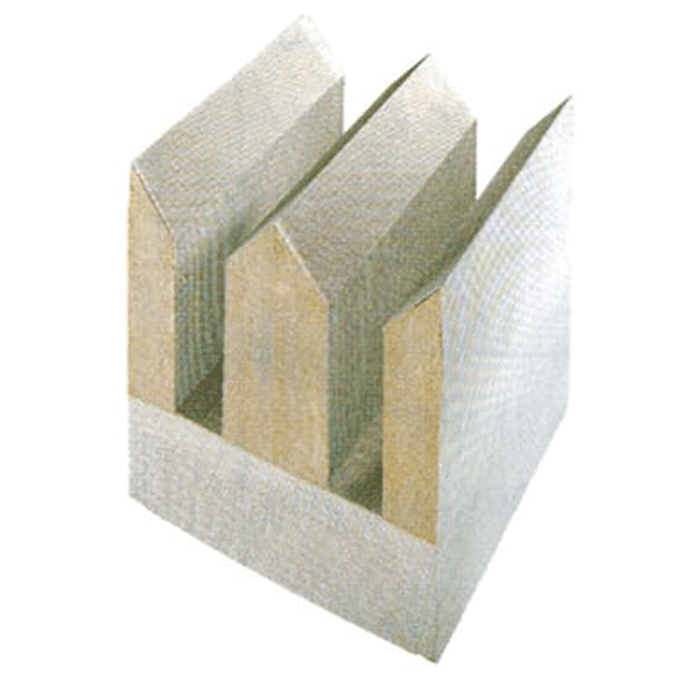

E-Element Anechoic Absorbing

The unique geometry of this wedge design offers a new dimension in anechoic chamber construction. These wedges have multiple parallel surfaces with tapered leading edges that alternate 90° out of phase with one another. This creates a sound absorbing array that achieves the desired cut-off frequency with less depth than conventional wedge designs.

Wedge Performance

The type of product being tested in the chamber will determine the cut-off frequency of the chamber wedges. Eckel wedges are available in a range of cut-off frequencies from 60 Hz to 250 Hz or higher.

Impedance Tube Method: ASTM-C 384-90a

A production sample method of individual wedges is tested to verify design, materials and cut-off frequency.

Achieve Optimum Performance

Eckel Noise Control Technologies. remains firmly committed to maintaining the high standards we have set for ourselves and the industry. Eckel will continue to develop and introduce innovative products that will allow our clients to conduct testing and research projects in perfect confidence. Eckel produces the world’s best anechoic chambers. Speak with an Eckel representative to learn more.

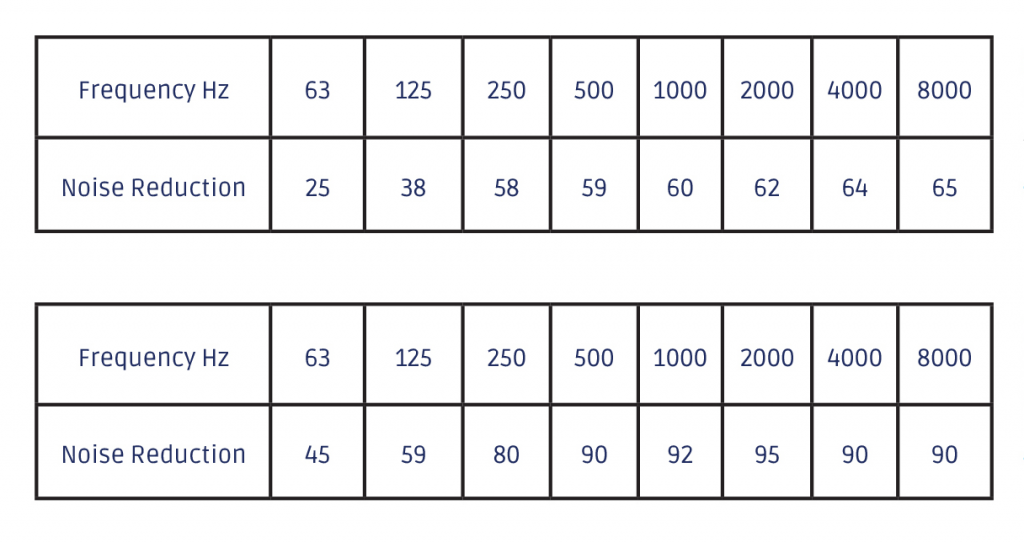

Single Wall Panel Chamber Noise Reduction Data

Measured noise reduction through a 4” (100mm) Acoustic panel Anechoic Chamber

Double Wall Panel Chamber Noise Reduction Data

Measured noise reduction through a 4” (100mm) Acoustic Panel and 8” (200mm) masonry wall.