| Sound Absorption | Encapsulated in a 2.0 mil (0.05 mm) flame guard polyethylene, Tested in accordance with ASTM C 423 and E 795: (Test Data below based on 30" x 120" Panel) |

|---|---|

| 125 Hz | 6.2 sabins |

| 250 Hz | 20.5 sabins |

| 500 Hz | 35.2 sabins |

| 1000 Hz | 34.5 sabins |

| 2000 Hz | 31.5 sabins |

| 4000 Hz | 33.1 sabins |

| NRC | 0.99, minimum |

| Panel Construction | Steel |

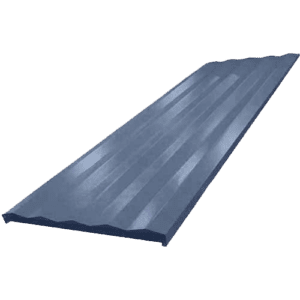

| Panel Thickness | 2 3/4″ (70mm) “V” ridged facing |

| Width | 30″ (760 mm) |

| Average Weight | 30” x 48” (762mm x 1168mm) 25lb/12kg 30” x 60” (762mm x 1524mm) 30lb/14kg 30” x 72” (762mm x 1829mm) 36lb/17kg 30” x 96” (762mm x 2338mm) 49lb/22kg 30” x 120” (762mm x 3048mm) 60lb/27kg |

| Acoustical Insulation | 2” (50 mm) thick, Density of not less than 1.5 pounds per cubic foot (24 kg/cubic m), Encapsulated in a 1.5 to 2 mil flame guard polyethylene, Fibrous glass, Fine fibred |

| Anchors & Fasteners | 1/4” (6 mm)-20 x 1” (25 mm) long bolts to attach mounting brackets to the panels, cadmium plated for steel panels, corrosion-resistant anchors for fastening brackets to substrate, See recommendations by panel manufacturer and by architect |

| Brackets | 4” (100 mm) of clearance between back of panel and mounting surface, Four 11ga (3mm) steel brackets per unit for attachment to walls and ceilings, Other bracket lengths available |

| Color | Linear White, Lux White, Beige or Warm Grey; Other colors available |

| Facing | 18ga (1.31 mm) electrogalvanized steel sheet, 3/32″ (2 mm) Perforations on 3/16″ (4.8 mm) staggered centers, V-ridged on 6” (150 mm) centers to a depth of 2-3/4” (70 mm) |

| Framing | 20ga (0.9 mm) electrogalvanized steel, Channel shaped, Two 1/4-20” (508mm) threaded inserts for each framing member for attachment of panel mounting brackets |

| Finish | Factory applied, Polyurethane enamel paint |

| Flame Spread | 10 Maximum |

| Smoke Density | 10 maximum |

Acoustic Panels, Eckel Functional Panel (EFP)

Eckel Functional Panel (EFP) Type-2 HD Steel

Heavy Duty (HD) EFPs are extra-durable, attractive, sound absorbing, and fire-resistant panels which can be spot located on walls and ceilings to achieve effective noise control.

Pre-engineered EFP panels come in a range of sizes and styles. They can be readily positioned within the host room to achieve optimal noise reduction performance. Available in aluminum or steel, panels can be customized and finished to fit and complement any architectural layout or interior design. Easy to install during new construction or as a retrofit item, EFPs are an economical and effective means to control noise and create ideal acoustic conditions.

EFPs turn a noisy room into quieter and more accommodating space better suited to its designed purpose.